Biosecurity: Relevance in the Broiler Production

17/10/2021

5 key points to promote a balanced intestinal microbiota in layer hens

16/11/2021Egg production in Brazil should achieve a new record in 2021 and reach the mark of 56 billion units, according to estimates by the Brazilian Association of Animal Protein (ABPA). There are 3 billion more than last year and, if it depends on the Brazilian people, the tendency is for the indexes to rise further in 2022. That’s because egg consumption in Brazil has only been increasing: currently the Brazilian consumes 251 eggs per year, 8.5% more than in 2019 and 167% more than 20 years ago.

In addition, Brazil should also consolidate itself as an exporter of eggs to countries like Saudi Arabia, Japan and Oman. In this context of growing expansion, issues such as biosecurity and management gain more prominence. Even more so because the possible economic losses arising from the lack of efficient biosecurity programs can be quite significant. Thus, investing in animal health and welfare directly contributes to better results.

In order to identify, manage and prevent outbreaks, to maintain the production quality and to serve an increasingly larger and more demanding market, commercial egg-laying establishments still have to pay attention to sanitary care. If you are looking for further details on how to comply with current legislation and to institute biosecurity measures, continue reading.

Responsibility on health and management legislation

As the Good Commercial Egg-Laying Production Practices Manual prepared by Embrapa in Brazil, attests, biosecurity is the adoption of a set of measures and operating procedures that aim to prevent, control and limit the exposure of chickens contained in a production system to disease-causing agents.

For certification and registration maintenance, poultry establishments must adhere to a series of rules and regulations established by the Ministry of Agriculture, Livestock and Food Supply (MAPA) for the production of commercial eggs.

Nelson Haga, business manager

Biocamp’s business manager, Nelson Haga, points out that a technical responsible (TR) has a fundamental role in this process, as he is the one who will be responsible for the implementation, maintenance and operation of biosecurity measures on the farms.

Poultry establishments in the consumer eggs sector must be registered with the State Animal Defense agencies, an agency linked to the Ministry of Agriculture. The owner of the establishment and the Technical Responsible Veterinarian (TR) registered with the Regional Council of Veterinary Medicine are responsible for the adaptations on the farms, complying with regulations and thus ensuring the biosecurity of the flock.

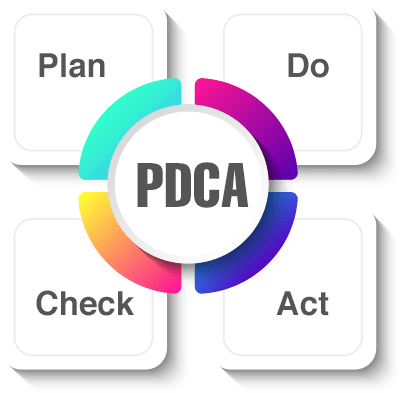

Ideally, it adopts the PDCA concept, which stands for plan, do, check and act so that all standards may be met. But what are these standards? The definitions are provided for in the Normative Instructions (IN) IN 56/2007, IN 59/2009, IN 36/2012, IN 10/2013, IN 08/2017 and IN 18/2017 and Nelson Haga highlights the 7 main biosecurity measures.

PDCA – Plan, Do, Check, Act

7 main biosecurity measures

Access gate

Access gate

It is the first physical isolation barrier on the farm, nucleus or house. It must be well posted with warning signs such as “Access only for authorized persons”, “No pets are allowed”, etc.

Disinfection arch

Disinfection arch

Disinfection arches should be located right after the access gate. The activation should preferably be automatic. Ideally, there is a barrier for the vehicle to reduce speed. A point of attention: vehicles must be clean before disinfection.

People access control

People access control

Access to poultry nucleus or houses must be restricted, controlled and registered in a guest book. People who are not employees of the nucleus will be allowed access only in case of need.

Isolation fences

Isolation fences

Isolation fences must have a minimum height of 1 meter and be 5 meters away from the poultry houses. The mesh of fences must restrict the access of free-living animals and other different species, such as cattle and horses.

Screening

Screening

All poultry houses must be screened with galvanized wire, nylon, plastic mesh, or other mesh material with an opening no larger than 1 inch (2.54 cm). The screen must cover the area from the floor to the ceiling of ??the house, preventing access of birds, domestic animals or free-living animals inside the houses with layer hens.

The screen is a barrier for entry of these animals, thus contributing to a reduction in feed waste, a reduction in cracked eggs and improvement in the viability and production of the flock.

Carcass processing

Carcass processing

Carcasses of dead chickens must be removed from the houses several times a day and placed in covered containers to prevent access by domestic animals. Carcasses must be transported to an appropriate location and processed in composters, dehydrators, composting accelerators or incinerators.

Water analysis

Water analysis

Water supplied to chickens must meet potability standards through annual examinations. The water must be chlorinated at a dosing of 3 ppm free chlorine.

Following these biosecurity standards in poultry production is essential to block and reduce the spreading of pathogen agents on farms. In addition, there is another measure that contributes to health and brings performance gains to layers: probiotics.

Added to feed or drink water, live microorganisms in probiotics colonize and balance the microbiota, stimulate defenses and feed conversion, contribute to increased production of prime eggs, as a result of better viability, better shell quality and egg utilization.

To find out what is the best program for your farm, contact Biocamp

![]()

Necessary biosecurity measures on farms | ||

| 3 km Minimum distance from the breeding farms of other establishments: • Commercial farms | Disinfection arch: open “U”-shaped or closed “O”-shaped • Automatic on/off sensor | Nucleus access gate • Isolation barrier |

| Notices and controls • Visit control | Ask the following questions • “When and what was the last company visited?” | Minimum clothing for entry of technicians in the houses • Plastic boot |

| Bath • It is not mandatory, but it is becoming more common as a health measure. | Isolation fence • Minimum height: 1 meter | Screens • Galvanized wire, nylon, plastic mesh |

| Collection of dead chickens • Remove several times a day | Composting of dead chickens • Safe method for normal daily mortalities | |

Equipment and other methods

Dehydrators/Disintegrators

- Carcasses deposited in a rotating drum and heated by burning of wood or wood pellets

- External temperature: 300ºC

- Internal temperature: 100 to 115 ºC

- In 4 to 6 hours, the weight is reduced by around 60%

- Material can be placed for composting or used as fertilizer.

- Capacity from 300 to 450 kg

Composting Accelerator

- Rotating cylinder

- For large volumes, with lower maintenance cost

- No need for burning of wood or wood pellets

- Continuous flow

Incinerator

- Two burning chambers: for animals killed at 800°C and for burning gases and vapors at 1,200°C

- Slower process

- Use of LPG

Manure treatment

- Drying in a covered area and paved floor forming windrows, using a stirrer

- Use of automatic mechanical stirrers

Rodent control

- Use of bait holder by tying

- Important: monthly change of bait

Water chlorination

- 3 ppm

- Annual Tests

Laboratory tests

- Farms must be monitored for salmonella by sending to the laboratory 300 g of feces, preferably fecal, or 4 drag swabs or disposable shoe protectors